Shandong Zhihua Pipe Industry Co., Ltd.

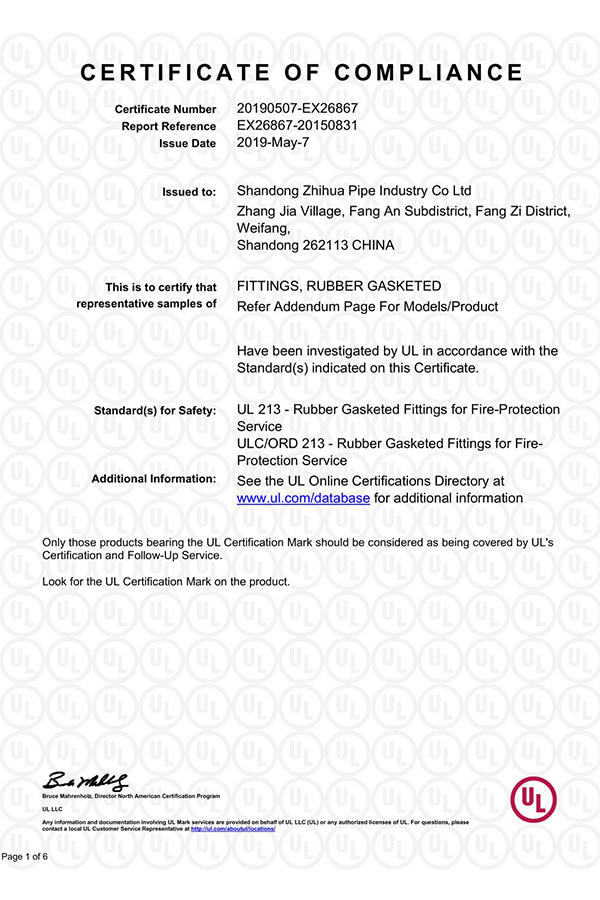

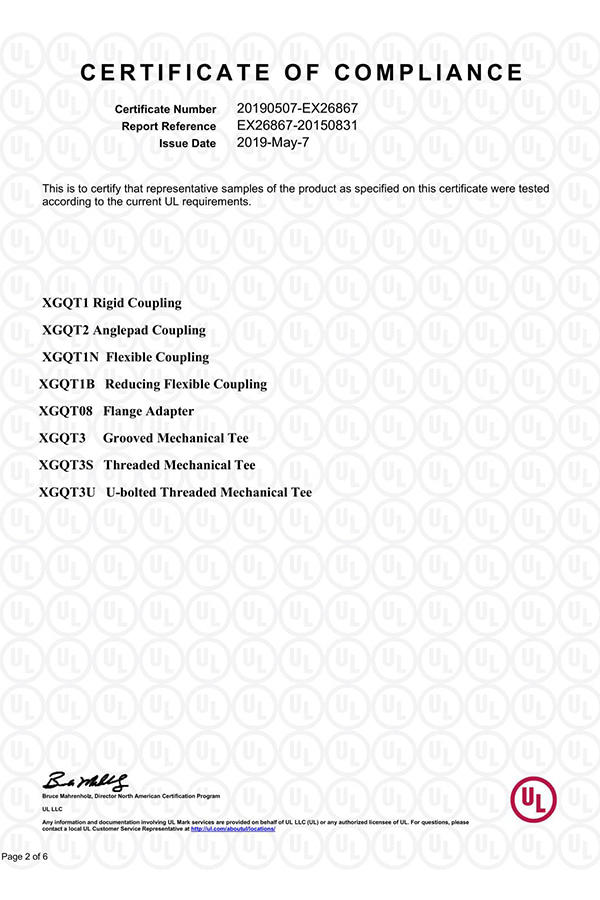

Zhihua is located in the beautiful international kite capital -- Weifang City is a collection of research and development, production, and sales of fire fittings, fire extinguishers, and other products of high-tech enterprises. The company was founded in 2007, after years of struggle, and enterprise-scale has been rapid development. Professional Threaded Mechanical Tee Suppliers and Manufacturers in China. At present,The company has passed the ISO9001 quality management system IS014001 environmental management system, and OHSAS18001 occupational health and safety certification, all products of the company through the fire voluntary certification, part of the products through the United States FM, UL, SG Sand CE certification.

English

English

Español

Español