How is a Mechanical Tee different from a regular Tee fitting?A Mechanical Tee is a type of pipe fitting that is different from a regular Tee fitting in terms of its installation method. While a regular Tee fitting is typically welded or soldered onto the pipe, a Mechanical Tee uses a mechanical joint to attach the Tee to the pipe.The mechanical joint of a Mechanical Tee usually consists of a gasket, a clamp, and a mechanical coupling. The gasket is inserted between the pipe and the Tee, and the clamp is then tightened to compress the gasket and create a seal. The mechanical coupling is used to secure the Tee to the pipe and to ensure that it does not come loose.This method of installation provides several advantages over traditional welding or soldering methods. It eliminates the need for hot work permits, reduces the risk of fire or explosion, and allows for faster and easier installation. Additionally, it allows for disassembly and reuse of the fitting if necessary, which can be especially beneficial in temporary installations.In summary, the main difference between a

Mechanical Tee and a regular Tee fitting is the method of installation. While a regular Tee fitting is welded or soldered onto the pipe, a Mechanical Tee uses a mechanical joint to attach the Tee to the pipe.

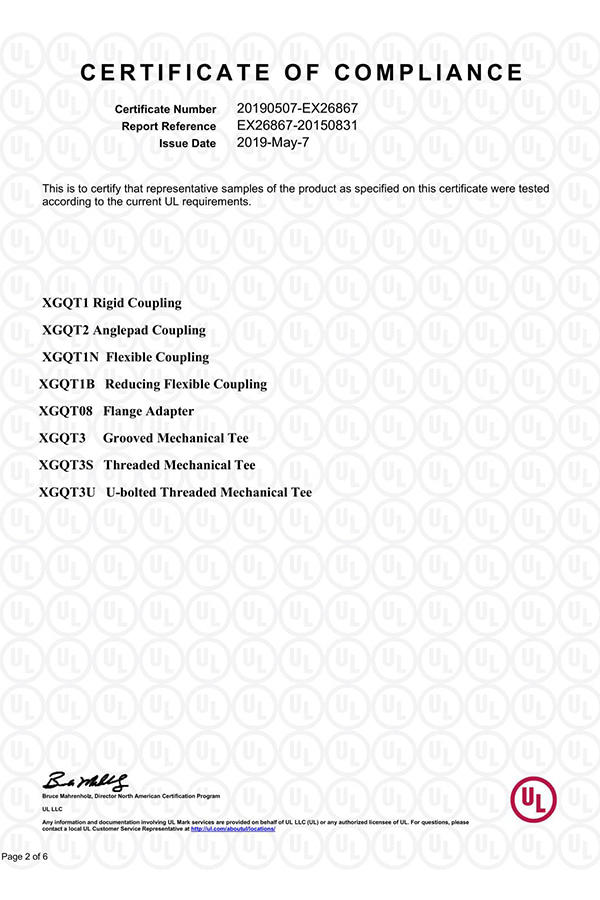

What are the different types of Mechanical Tees?There are several types of Mechanical Tees available, and the specific type of Mechanical Tee used will depend on the application and the type of pipe being used. Here are some of the most common types of Mechanical Tees:Grooved Mechanical Tee: This type of Mechanical Tee is designed to be used with grooved-end pipe, which has a groove around the circumference of the pipe that allows for easy installation of the fitting. Grooved Mechanical Tees are often used in fire protection systems, HVAC systems, and other applications where quick installation and removal is important.Threaded Mechanical Tee: This type of Mechanical Tee is designed to be used with threaded pipe, which has threads on the end of the pipe that allow for easy installation of the fitting. Threaded Mechanical Tees are often used in plumbing and gas distribution systems.Flanged Mechanical Tee: This type of Mechanical Tee is designed to be used with flanged-end pipe, which has a flange on the end of the pipe that allows for easy installation of the fitting. Flanged Mechanical Tees are often used in water treatment plants, chemical processing facilities, and other industrial applications.Welded Mechanical Tee: This type of

Mechanical Tee is designed to be welded onto the pipe, but it still uses a mechanical joint to connect the Tee to the pipe. Welded Mechanical Tees are often used in high-pressure applications where a strong, reliable connection is required.Compression Mechanical Tee: This type of Mechanical Tee uses a compression fitting to connect the Tee to the pipe. Compression Mechanical Tees are often used in low-pressure applications, such as irrigation systems and other agricultural applications.These are just a few examples of the different types of Mechanical Tees that are available. The specific type of Mechanical Tee used will depend on the application, the type of pipe being used, and the specific requirements of the installation.

How does a Mechanical Tee work?A Mechanical Tee works by creating a mechanical joint between the Tee fitting and the pipe, which provides a secure and leak-free connection. The mechanical joint is created by a combination of a gasket, a clamp, and a mechanical coupling.Here is how a Mechanical Tee typically works:The pipe is prepared by cleaning and deburring the end to ensure a smooth surface for the gasket to seal against.The gasket is placed around the end of the pipe, and the Mechanical Tee is positioned over the gasket.The clamp is then tightened around the Mechanical Tee, compressing the gasket between the Tee and the pipe. The clamp is tightened to a specific torque value to ensure a proper seal.The mechanical coupling is then used to secure the Tee to the pipe, providing additional support and preventing the Tee from becoming loose.Once the Mechanical Tee is installed, it provides a strong and reliable connection between the Tee and the pipe. This type of connection can be especially beneficial in applications where the pipe may need to be disassembled and reassembled, as the Mechanical Tee can be easily removed and reinstalled without damaging the pipe or the Tee.Overall, the Mechanical Tee works by using a combination of a gasket, a clamp, and a mechanical coupling to create a secure and leak-free connection between the Tee fitting and the pipe.

English

English

Español

Español