How does a grooved coupling work?A

grooved coupling consists of two components: a grooved pipe end and a gasket that fits into the groove. When the two components are pressed together, the gasket is compressed between the two pipe ends, creating a tight seal.The grooved pipe end has a groove machined into the pipe's outer surface. The gasket is typically made of rubber or other flexible material and is designed to fit into the groove. The gasket creates a seal between the two pipe ends, preventing leaks.The grooved pipe ends are connected by a clamp that is tightened around the outside of the grooved pipe ends. The clamp is usually made of metal and is designed to apply a consistent pressure around the entire circumference of the pipe, ensuring a secure and reliable connection.Grooved couplings are designed to be easy to install and can be used in a variety of piping applications, including HVAC, plumbing, and fire protection systems. They offer several advantages over other types of pipe joints, including ease of installation, flexibility, and the ability to accommodate thermal expansion and contraction.

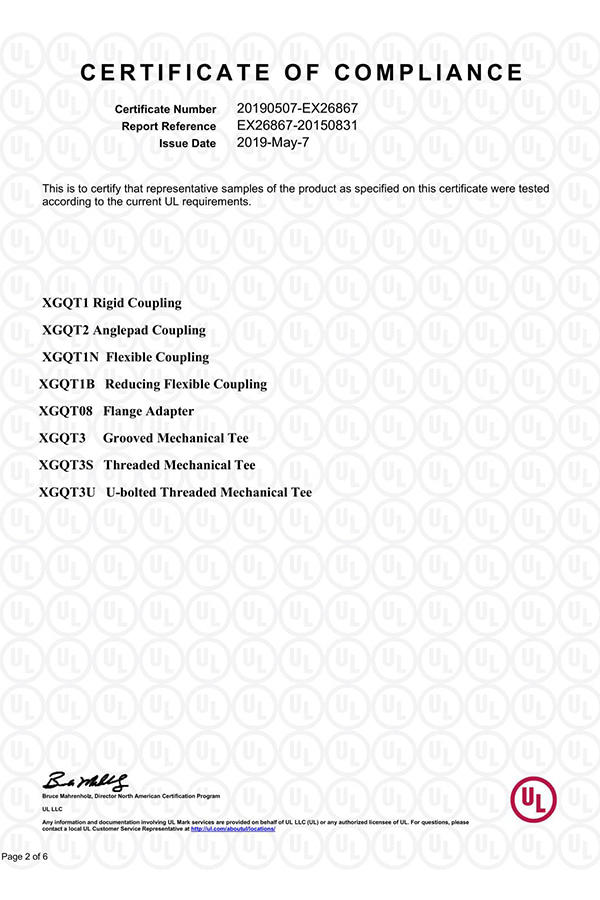

What are the different types of grooved couplings?There are several different types of grooved couplings available, each designed for specific applications. Here are some of the most common types:Standard rigid grooved couplings: These couplings are used to connect two pipes together and provide a rigid, permanent joint. They are typically made of ductile iron or stainless steel.Flexible

grooved couplings: These couplings are designed to absorb vibration and allow for thermal expansion and contraction in the piping system. They are commonly used in HVAC and plumbing systems and are made of materials such as rubber or stainless steel.Flanged grooved couplings: These couplings are designed to connect grooved piping systems to flanged piping systems. They feature a flange on one end and a grooved end on the other, allowing for easy connection to both types of piping systems.Grooved mechanical tees: These are used to create a branch in a piping system. They consist of a grooved outlet and a grooved pipe end, with a gasket and clamp used to create a tight seal.Grooved reducing couplings: These are used to connect pipes of different sizes together. They feature two grooved pipe ends of different sizes, connected by a gasket and clamp.Grooved adapters: These are used to connect grooved piping systems to other types of piping systems, such as threaded or welded systems.Each type of grooved coupling has its own unique features and benefits, and the right type of coupling for a specific application will depend on factors such as pipe size, material, and system requirements.

What are some common mistakes to avoid when using grooved couplings?Here are some common mistakes to avoid when using grooved couplings:Incorrect installation torque: It is important to follow the manufacturer's recommended torque values when installing grooved couplings. Under-tightening can result in leaks, while over-tightening can damage the coupling, pipe or gasket, compromising the joint's integrity.Improper gasket selection: Selecting the wrong type of gasket or using a damaged gasket can result in leaks or joint failure. Always use the correct type of gasket specified by the manufacturer and inspect it for damage before installation.Misaligned pipes: Misaligned pipes can cause stress on the coupling, which can lead to joint failure. Ensure that the pipes are properly aligned before tightening the coupling.Incorrect pipe preparation: It is important to properly clean and prepare the pipe ends before installing grooved couplings. Failure to do so can result in leaks or joint failure.Incorrect coupling selection: Using the wrong type of coupling for a specific application can result in leaks or joint failure. Always use the correct type of coupling specified by the manufacturer for the specific piping system.Improper handling of couplings: Dropping, dragging, or mishandling grooved couplings can damage them and compromise their integrity. Always handle couplings with care.Inadequate support: Lack of proper support can cause undue stress on the grooved coupling joint and can lead to joint failure. Make sure that the piping system is adequately supported to prevent undue stress on the coupling.By avoiding these common mistakes, grooved couplings can be a reliable and efficient option for joining pipes in a wide range of applications.

English

English

Español

Español